Description

FLOWMATIC® 09 BULK BAG FILLING – HIGH RATE FIBC FILLING EQUIPMENT WITH NET WEIGHING FOR SINGLE HANDLE BULK BAGS

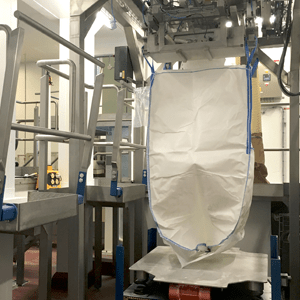

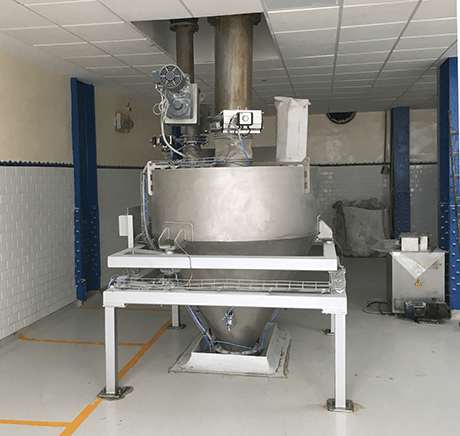

The FlowMatic® 09 bulk bag filler enables high-speed net weighing and loading for single handle FIBC’s. This model represents the complete system solution for automatic net weighing packaging operations for single loop bulk bags, FIBC, super sacks, jumbo bags, big bags (dosing/packaging/conveying) requirements.

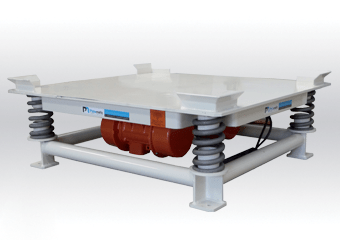

The FlowMatic® 09 super sack filler is equipped with all the necessary packaging options to minimize human operator intervention. The handling of your single handle bulk bags is automated: weighed pre-dosing bulk bag filling hopper, inflatable containment seal, bulk bag rotating head grip, height-adjustable deck via pneumatic cylinder, bulk bag pre-forming fan, optional commercial weighing, vibrating densification table, pallet unstacker, and FIBC belt conveyor.

The FlowMatic 09 complete FIBC filling system is intended for continuous use at high speed operation by integrating the right features of automated tasks in sequence.

-

Automation5

-

Rate5

-

Overall dimensions3

Equipment advantages

- Hydraulic tension hook

- Commercial weighing with net weight

- Pre-dosing hopper

- Conveyor and automation

Media

View our equipment in videos

FlowMatic® 08 big bag filling system

Bulk bag filling range

View our equipment in photos

Big bag 1 loop

FlowMatic®08 big bag filling station for big bags with one handle including a feed hopper equipped with a butterfly valve that allows or not to close it.

Bulk bag filling system

The big bag conditioner is provided with a simple hanging system specially designed for big bags for one. An inflatable seal completes the filling head.

Sugar packaging

The sugar is packed in big bags for storage.

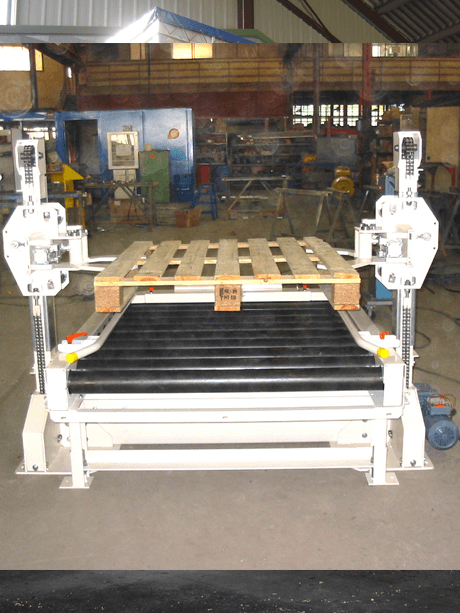

Pallet unstacker

The pallet unstacker is used to automate the big bag filling line.

Pallet unstacker

The stacked pallets are stored in the warehouse and then feed one by one the big bag packing station via a motorized conveyor.

Bulk bag filling head

Mobile station for packing cement in big bags.

Big bag filling with platform

The access platform facilitates the operator's access to the big bag filling spout.

Big bag filling line

Industrial production line with filling station for big bags of sugar.

Conveyor on bulk bag filling station

Once conditioned, the big bag is placed on the pallet and removed by a motorized roller conveyor, thus optimizing the flow rate of the big bag conditioning line.

Automatic bulk bag filling

The big bag is suspended on the forks during the filling phase.

Automatic process line

Industrial production line for conditioning big bags with white sugar and crystal sugar.

Big bag filling hopper

Complete process line for the preparation and management of premixes.

Features

Technical specification

| Rate | 40 to 60 bulk bags/h. |

|---|---|

| Capacity | 2 tons/bulk bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 7.8 kW |

| Compressed air consumption | 2.1 Nm³/h. |

| Dust removal rate | 600 m³/h. |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 1.4 kW

Operating pressure: 6 bar

Input 4-20 mA: 1

Digital input: 14

Digital output: 9

Accuracy of the weighing chain: +/- 500 grams

Maximum big bag dimensions length * Width * Height: 1,300 * 1,300 * 2,400 mm

Equipment integrated into the Flowmatic® 08 model:

- Platform

- Conveyor belt

- Hook for fastening the handle

- Pre-inflation fan

- Hydraulic tension cylinder

- Load cells

- Shaping cylinder

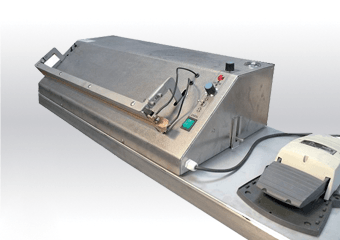

- Filling head

- Pre-dosing hopper

- Dosing screw

- Supply hopper

Options

Case studies

Receive our quotation in 3 clicks!