Dedicated feeders and weighing conveyors

The DosingMatic® Master integrates precise technical equipment to guarantee simultaneous and precise dosing of the different ingredients, ensuring optimal productivity and constant quality of your premixes.

The dosingMatic Master® integrates several volumetric feeders with a weighing conveyor dedicated to each feeder, which allows the positioning of the premix tank to be filled under the feeder concerned.

Each feeder having its dedicated dosing loop, the complete cycle time is short and the premix production is very high. All products are dosed simultaneously in the dedicated premix. This innovative system is ideal for industries requiring precise and reliable dosing of ingredients and powders with a large number of batches.

- Simultaneous and precise dosing for consistent quality of premixes

- Versatility and automation

- Robust and compliant structure

- High productivity

- Advanced technical equipment for optimal efficiency

The DosingMatic® Master process line is an automated and versatile dosing solution with advanced technical specifications for ingredients and powders.

The technical characteristics of the DosingMatic® Master

- Support structure in closed profiles: made of 304 stainless steel (or steel depending on option), this robust and durable structure is designed to withstand the most demanding industrial conditions. The floor fixing feet ensure optimal stability.

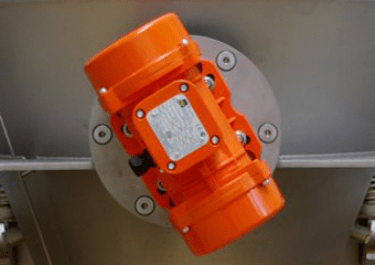

- Standard bag emptying hopper: made of 304 stainless steel, this hopper is equipped with a closing cover with sensor, a vibrating bar level probe on SMS connection, a flow aid vibrator, a magnetic bar and complies with current regulations according to your needs and powders handled.

- D11, D12, D13 feeders or DVIB vibrating feeders: these high-performance feeders are made of 304 stainless steel, with a base from the standard Palamatic Process models and a standard dosing tube. It is equipped with a dosing tool motor (0.37 kW), a homogenization motor (0.75 kW), a product-specific dosing tool and complies with current regulations.

- Weighing and transfer/conveyor unit: designed in 304 stainless steel, this unit supports the weighing belt conveyor. It is equipped with operating sensors and a containment cover for connection to the dust collection system.

. - Weighing Belt Conveyor: this 500mm long and 400mm wide conveyor features a galvanized frame and food grade belt. It is equipped with a position sensor, a speed of 14 m./min at 50 Hz, a scale with a capacity of 15 kg and a scale of 5g excluding ML, as well as a weight indicator local.

Application areas of the DosingMatic® Master

The DosingMatic® Master is ideal for many industrial applications, such as:

- Food industry: precise dosing of ingredients for food and beverage production, preparation of premixes and premixes.

- Bakery and industrial pastry industry: large volumes of production batches for high reliability feeding of mixers.

- Pharmaceutical industry: dosage of powders and active ingredients for the manufacture of medicines.

- Chemical industry: dosing of powders and granules for the production of chemicals and materials in compounding applications for example.

Why choose DosingMatic® Master from Palamatic Process?

By choosing the DosingMatic® Master, you benefit from the expertise and experience of Palamatic Process, a leader in the design and manufacture of dosing machines and automation systems. Our commitment to quality, innovation and customer satisfaction ensures that the DosingMatic® Master will meet your requirements for performance and reliability.

To learn more about the DosingMatic® Master and discover how this solution can optimize your dosing process, contact us today. Our experts are available to assist you in choosing the solution best suited to your needs. Take advantage of our know-how to improve the quality and productivity of your industrial process with the DosingMatic® Master solution from Palamatic Process.