1. Storage and dosing of dry ingredients

The storage and management of raw materials is the starting point of any production process. There are various solutions for storing bulk ingredients, but the most common option is the palletization of bags. The ingredients for the recipe can also be stored in bulk in tanks or silos. It is then a question of large quantities, usually flour or sugar, of key dry ingredients for making baked goods.

Manufacturers will have their supplier delivery flour, which is transferred from trucks to their storage silos. Once in the silo, the flour is transferred by pneumatic conveying into receiving hoppers responsible for dosing the necessary quantity by batch into a kneader.

2. Making the dough

The mixing of ingredients (sugar, flour, conditioner, yeast, etc.) plays an important role when it comes to producing sandwich bread. A pre-mixing phase for the hydration and homogenization of the ingredients can also be integrated.

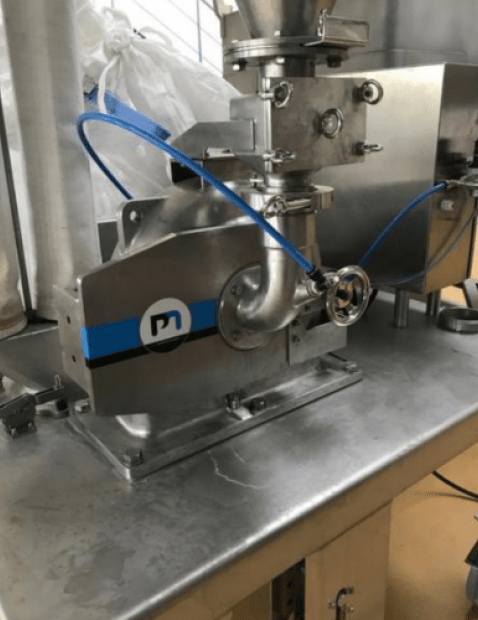

Also, the preparation of the dough with the kneading equipment guarantees the quality of the bread coming out of the production line. Therefore, it is necessary to transfer and dose the ingredients in a quick and meticulous way to respond to the required production rate.

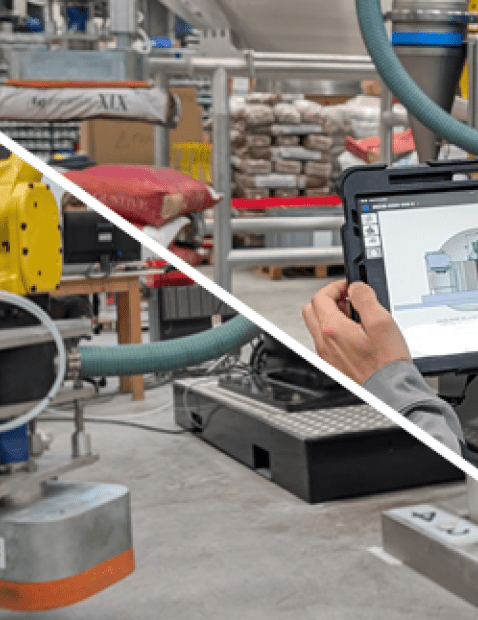

Industries that need to optimize their production costs must automate the dosing of ingredients, production cycles, washing cycles, etc., using equipment with automated kneading systems, carousels of batch kneaders, batch kneaders or continuous kneaders.

The transformation of flour into bread includes the step of adding “minor ingredients”, mainly in the form of powder, such as salt, sugar, yeast, sourdough, preservatives, flavorings, etc.

Some products in liquid form can also be incorporated into the recipe just before kneading, such as water or milk.

Do you need information about bakery processes?

I am available to advise you.

Guillaume, powder expert

3. Fermentation et cuisson

Once the dough is fermented, it is processed through various machines for cutting, weighing, rolling, and formed to the size of the baking mold. The next step is baking which is the most important because it largely determines the quality of the finished product.

Once this dough is cooked, it must be unmolded. On most production lines, robots take care of demolding. The sandwich bread is then cut into slices, before being bagged automatically.

We can offer you turnkey solutions for your production line. Our BakeFlow®1, BakeFlow®2 and BakeFlow®3 process lines have been specially designed for the Bakery, Viennese Pastry and Pastry sector:

BakeFlow®1: automated flour transfer line ensures the loading of bakery kneaders in a fully automated and controlled manner.

BakeFlow®2: automatic loading line for mixers with ingredients, it represents the multi-ingredient version of the BakeFlow®1 solution.

BakeFlow®3: dosing and mixing of dry ingredients used in industrial bakery recipes. The loading of the mixers is thus automated and traceability ensured thanks to industrial automation.