1. Vacuum lifting systems

In production plants, the use of sacks is mandatory for handling raw materials. Some manufacturing processes require the handling of many bags per hour and operators soon find themselves carrying several tons per day.

Palamatic offers a range of vacuum lifting devices that allow for effortless lifting of all types of bags. The bags are handled by a suction pad. These ergonomic handling systems incorporate a handle that allows operators to lift or lower the load (the bag) without any effort.

Find out more about how a vacuum bag handler works or see our dedicated equipment, the Manis® Palamatic sack manipulator.

Are you looking for a bag handling system?

I am here to help you with your study.

Guillaume, expert in bag handling

2. The importance of eliminating risks to operators

In addition to the ease of lifting, operational safety is ensured by a valve system that prevents any risk of falling. The vacuum created by the suction pump is maintained between the valve and the suction pad to ensure a slow and controlled descent of the load.

In order to best adapt the handling solutions offered by Palamatic, our sales teams study the ergonomics of handling by integrating this lifting equipment on wall-mounted jib cranes, bi-articulated jib cranes, mobile jib cranes or on overhead cranes.

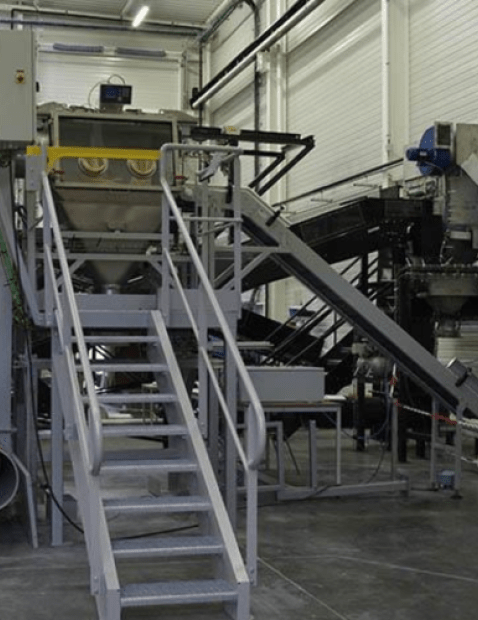

The installation of handling systems on bag emptying stations gives operators a comfortable working environment and ensures the elimination of risks linked to manual handling.

For emptying sacks, palletising or depalletising 25kg sacks, handling aid solutions exist! Contact our sales department to receive a quote for your vacuum lifting system.