Description

High-speed, automated big bag emptying station - FlowMatic® EF500

Automatic deconditioning, hydraulic gripping of the big bag without operator intervention.

The big bag discharging station is fed by a set of motorized conveyors that supply the hydraulic gripper. A pallet stacker ensures the evacuation of the big bag handling pallets. The so-called manual operations consist of the handling by a forklift operator of the stacks of pallets as well as the big bags to be unloaded. The forklift operator places the big bag pallets on the conveyors.

The big bags are fully automatically handled by the hydraulic gripper system mounted on a bridge crane and ensuring the translations above the discharge hoppers. The empty big bag is automatically discharged to a baler or big bag compactor.

Operation mode:

1. Placing of loaded big bags by a forklift on the motorized roller conveyor line(s) (several lines = several products possible for recipe formulation, with "picking")

2. Automatic management of the accumulation (storage and advancement) of the big bags pending emptying by the supervision automaton.

3. Automatic selection of the big bag to be emptied on the dedicated conveyor line (in applications requiring recipe management)

4. Automatic gripping of the loaded big bag by the hydraulic gripper mounted on a motorized trolley (handling crane)

5. Automatic big bag feed above the emptying station

6. The containment doors of the EasyFlow® EF500 Big Bag Emptying Station enclosure open and close automatically to ensure maximum containment during the big bag breaking phases (this containment enclosure may be an option).

7. Lowering the big bag onto cutting blades, cutting through the bottom of the big bag

8. Management of the pressure of the hydraulic clamp during the big bag emptying / breaking phase

9. Automatic feed + automatic release of the big bag into the baler or big bag compactor

10. Management of the empty pallet: automatic sending to a pallet stacker

11. Back of the gripper for gripping the next big bag

-

Rate4

-

Automation5

Cutting of the big bag:

The big bag is cut by cross or "U" shaped blades depending on the big bag design. For big bags with an outlet spout, the cutting system will be a "U" shaped system. Big bags with a bottomless bottom are cut by cross or diamond points as a preference.

For difficult flowing products, massage cylinders can be installed on the discharging station. These hydraulic or pneumatic massage cylinders can be used to force the extraction of the product.

Big bag gripping clamp :

The big bag gripper is the heart of the Palamatic Process easyFlow® EF500 system. This gripper has its own hydraulic unit. It is designed with a double clamping system to hold both full and empty big bags. This double clamping system is fully synchronized and remotely controlled with a chain of safety sensors depending on the cycle. This hydraulic big bag handling clamp makes the presence of an operator on the emptying station unnecessary. The movement of the clamp at the different stations is as follows:

1. Gripping of filled big bags

2. Cracking hopper / FIBC discharge

3. Drop zone: big bag compactor, waste bin or baler

This displacement is managed automatically by a positioning system supervised by the PLC.

This automatic big bag emptying system integrates a large number of features specific to each of our customers. Do not hesitate to contact our pre-project department to study your automatic big bag emptying solution.

Equipment advantages

- No operator

- Automatic cutting

- Automatic big bag gripping

- Automatic big bag opening

- Automatic big bag discharging

- Automatic evacuation of the emptied big bag

Media

View our equipment in videos

Gripping by hydraulic clamp - EF500

View our equipment in photos

Hydraulic clamp for discharging

Big bag gripping by hydraulic clamp.

Secondary jaw for big bag discharge

Big bag discharged automatically and held by the secondary jaw.

Automatic big bag emptying clamp

Gripper for 100% automatic big bag discharging.

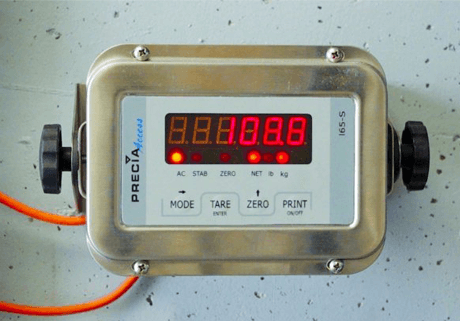

Dust removal from the big bag emptying system

Dust collection network for the whole big bag emptying system.

Pallet stacker for big bag unloading

Pallet stacker on conveyor feeding the big bag emptying system.

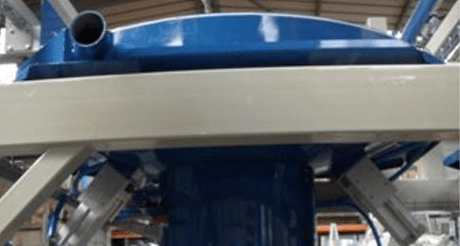

Contained and hig rate rate big bag emptying system

Complete contained high rate big bag emptying system.

Discharging the big bag

Big bag unloading thanks to an hydraulic clamp EasyFlow® EF500.

Features

Technical specification

| Rate | 1 to 25 big bags/h. |

|---|---|

| Manufacturing materials | Painted steel, 304L stainless steel, 316L stainless steel |

| Finishing touches | RAL 9006, micro-blasted, electropolishing |

| Installed power |

- Pneumatic 6 bar - Hydraulic - Electric 400 V - 50Hz - 5 to 10 Kw |

| Required dust collecting rate (optional) | 3,000 m³/h. |

| Maximum dimensions of the big bags (length* width * height) | 1,100* 1,100 * 1,200 mm |

| Lifting capacity | 1 000 daN |

| Big bag gripping | Hydraulic clamp with 2 synchronized arms |

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

High-rate big bag unloading system for the plastics and polymer industry

Processed powders: PET resin granules and PET flakes - Fully automated big bag discharging line - Big bag compaction at the end of the lineInsect breeding

Quartz production process

Processed powder: Quartz - Quartz production process - A customized solution to automate the unloading of big bags for a world leader in the production of high-purity quartz.Energy

Nickel hydroxide production process

Processed powder: nickel sulfate - Tailor-made solution to increase nickel hydroxide production in response to growing demand for electric vehicle batteries.Energy

Optimising the handling and unloading of big bags to improve safety and production

Powders treated: hygroscopic powders such as metal sulphates Optimising the handling and unloading of big bags to improve safety and productionEnergy

Optimising automated bulk bag discharge for lithium powders

Powders handled: Lithium carbonate (Li₂CO₃), iron oxide (Fe₃O₄), lithium Optimising automated bulk bag discharge for lithium powdersEnergy