Description

Pneumatic conveying - Dense phase pressure conveying - Pressure vessel - Suitable for abrasive or fragile bulk products - MaxFlo®

Rate: 2 to 100 t./h.

Conveying of products with high abrasiveness

This dense phase pressure conveying is convenient for very abrasive products. This equipment ensures slow and delicate transport of granules, powders and mixtures, with less compressed air and energy consumption.

High flow, low speed and long distance conveying

The dense phase pneumatic conveying is a system particularly adapted to very abrasive materials.

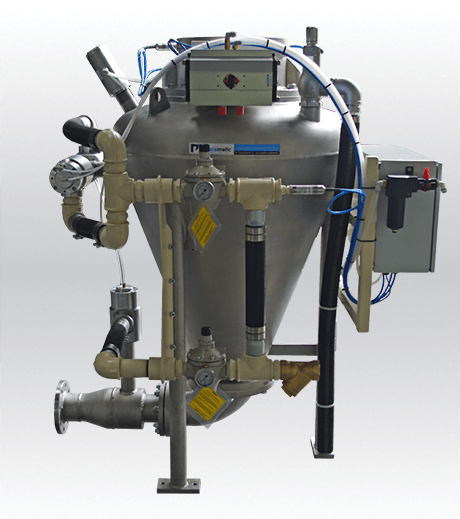

Palamatic Process offers the procedure Macawber/Mactenn that uses the Inflatek® valve in order to transfer the material to the powder handling manufacturing line. This dense phase pressure conveyor system is suitable for very abrasive product, at all throughput and all temperatures.

Operating mode:

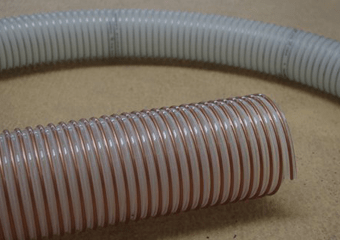

In this type of pneumatic conveying, the valve cuts the product flow below the transfer tank. This tank or transfer sluice is fitted with a double case and a special output elbow that allows to send the product slowly to the pneumatic conveyor piping.

This completely patented thrust dense phase (pneumatic) sluice procedure allows us to ensure the bends for up to two years against abrasion, and to provide a guarantee of 1,000,000 operating valve cycles before general revision. Furthermore, the dispatching valve can be cooled by water circulation, which allows to send products at very high temperature in the process.

- Product is inserted in the sluice

- The valve closes in the product flow

- Controlled air introduction

- The operation is renewed up to cancellation

Its innovative yet simple design is the reason it is so versatile in bulk material conveying. Having only one moving part, it is low on maintenance and does not consume manpower or energy in its operation. Fully compliant with ATEX standards and can meet the high temperature needs of many processes.

Utilizing dense phase technology to achieve the lowest possible transfer velocity at the most optimal energy conservation. The leak-proof design facilitates a clean and dust free work environment. Can work in temperatures as high as 350°C and is compliant to ATEX standards.

-

Rate5

-

Fragile material5

-

Abrasive material5

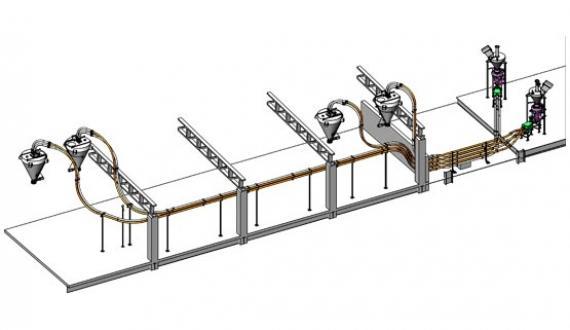

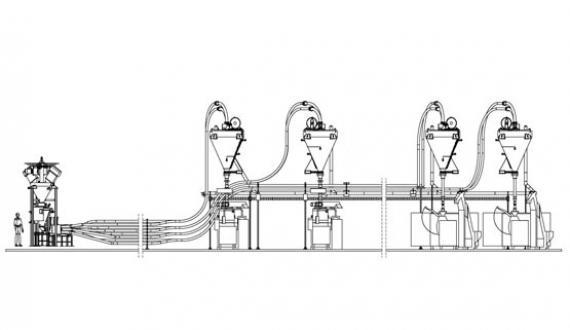

Example drawing of installation

Diagram of a dense phase pneumatic convey system for the feeding of bulk bag filling stations

2 feeding silos

4 packaging lines

DENSE PHASE CONVEYING solutions

Dense phase - Full pipeline

- The difference in pressure is higher

- Material velocities are at their lowest

- Material fills the pipeline

Dense Phase - Slug Flow

- Dense phase dune flow

- The difference in pressure is medium-high

- Material velocities are low

- Material forms dunes while being conveyed

Dense Phase - Bed Flow

- The difference in pressure is medium

- Material velocities are medium to high

- The saltation velocity is achieved for some particles in the material which partially fluidises to convey above a bed of material moving slower

Lean Phase - Dilute Phase

- The difference in pressure is lower

- Material velocity is highest

- The saltation velocity for all the particles is achieved which causes the material as a whole to be conveyed within the gas stream

Equipment advantages

- Reduce abrasion and segregation

- Long distances conveying

- Important flows

- Optimized design to meet special needs

- All industries

- Low maintenance

- Atex standards

- Very high temperatures operation

Media

View our equipment in videos

Pressure vessel dense phase pneumatic conveying

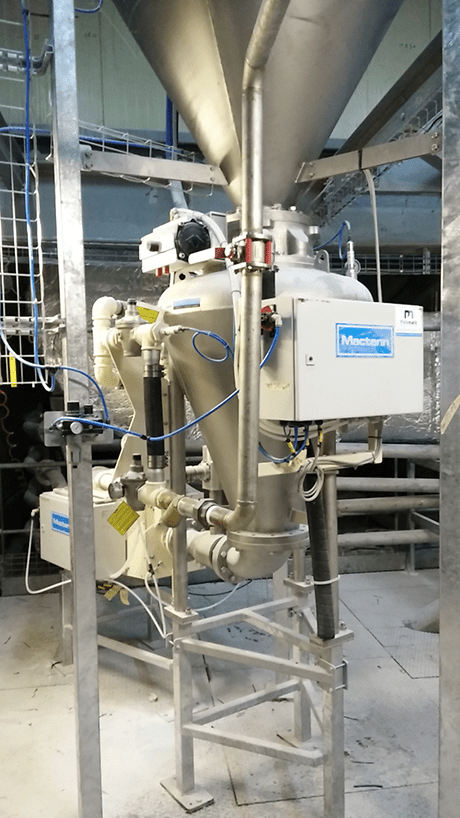

The dense phase pneumatic conveying is a system particularly adapted to very abrasive materials.

Palamatic Process offers the procedure Macawber/Mactenn that uses the Inflatek® valve in order to transfer the material to the powder handling manufacturing line. This dense phase pressure conveyor system is suitable for very abrasive product, at all throughput and all temperatures.

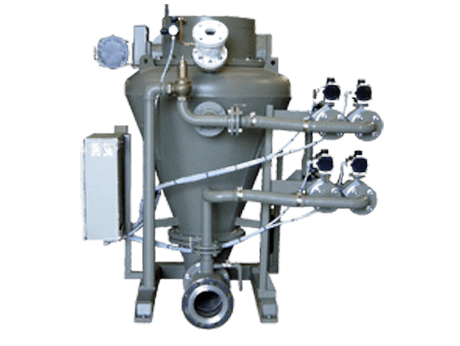

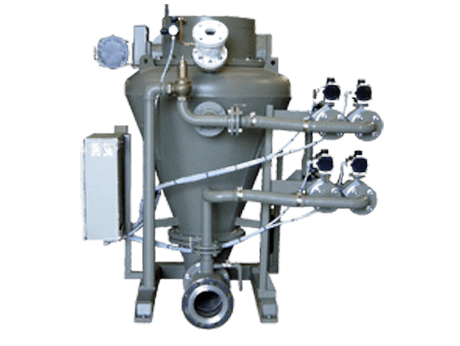

MaxFlo® Pneumatic Conveying System

This dense phase pressure conveying is convenient for very abrasive products. This equipment ensures slow and delicate transport of granules, powders and mixtures, with less compressed air and energy consumption.

Low-Velocity, Dense-Phase Pneumatic Conveying System

Low-Velocity, Dense-Phase Pneumatic Conveying System

View our equipment in photos

Conveying of refined white sugar and brown sugar

Each conveying airlock is designed to provide 9 t/h. at 12t/h. of sugar conveying rate.

Dense phase pneumatic conveying

Conveying of highly abrasive bulk materials.

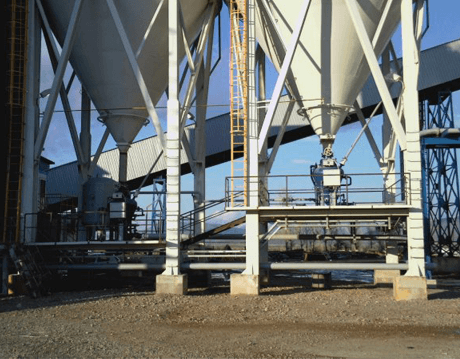

Assembly conveying system

Design of a pneumatic conveying system for the feeding of sugar packing machines:

- 2 industrial silos

- 4 packing processing lines

Advanced pneumatic conveying system

Dense phase pressure conveying range.

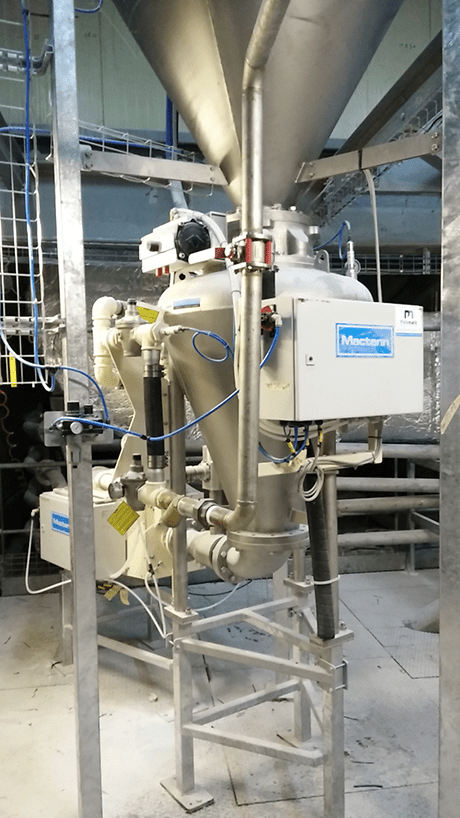

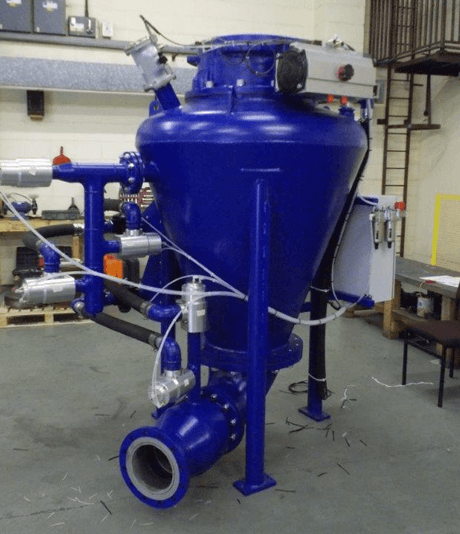

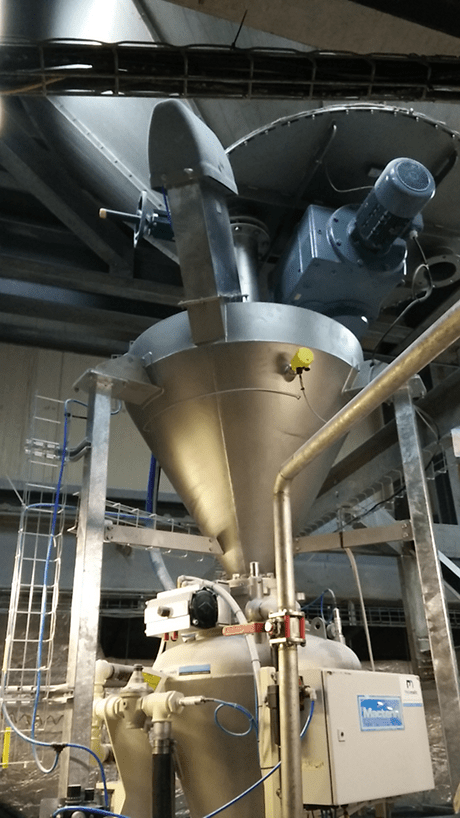

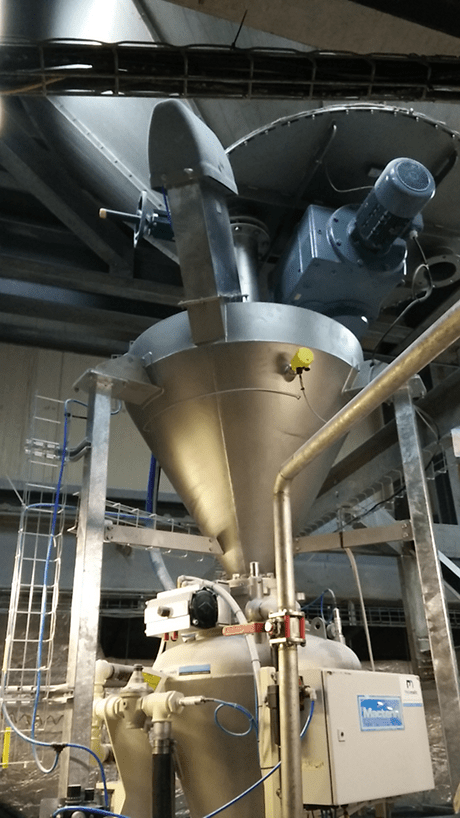

Pneumatic conveying pressure vessel

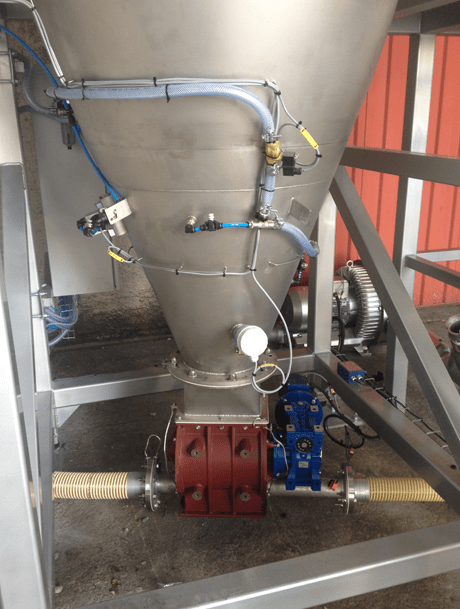

Dense phase pneumatic conveying on processing line

Industrial production lines involving raw ingredients and bulk materials handling.

Pneumatic conveying pressure vessel

This high-density pneumatic conveyor is suitable for very abrasive raw ingredients, at all flow rates and temperatures.

Pneumatic conveying pressure vessel

Pneumatic conveyor for for industrial production lines involving raw ingredients and bulk materials handling.

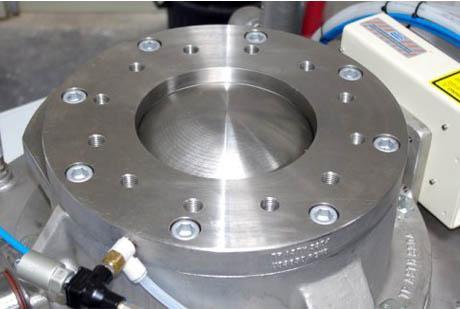

Valve for break in the product stream

Special valve for a cut-off in the flow of the bulk material.

Pneumatic conveying cyclone

Dense phase pneumatic conveying for raw ingredients and bulk materials handling.

Dense phase pneumatic conveying with integrated stainless steel hopper

This patented high-density pneumatic airlock valve guarantees elbows for up to 2 years against abrasion.

pneumatic sugar conveying

The pressure vessel successively feeds the 8 filling machines at a flow rate of 9t./h. or 12t./h.

Pressure pneumatic conving

The pressure tank is gravitarily supplied through a specific valve that cuts the bulk material flow at the end of the filling process and ensures a tight seal through its inflatable seal.

Bulk powder pneumatic conveyor

Airlock for conveying bulk materials into a reactor on a powder storage and conveying line.

Features

Technical specification

KEY FEATURES:

- Method of transfer consumes minimal air in order to convey fragile materials such as food products or convey heavy abrasive materials like iron oxides.

- Less air usage means smaller compressors, smaller exhaust filters, and thus lower power cost.

- A fully contained transfer system will prevent the opportunity for dust escaping into your work place.

- When compared to dilute phase, our velocities are much lower which translates to longer lasting pipes and low maintenance required.

- Operates on-demand only and completely automated to reduce energy consumption without the constant attendance from an operator.

MINIMAXFLO® model:

|

Models |

MINIMAXFLO® dimensions in mm |

Weight in kg |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

A |

B |

C |

D |

E |

F |

G |

H |

I |

|

|

15/4-2 |

718 |

485 |

803 |

25/40/50 |

725 |

330 |

405 |

100 |

20 |

109 |

|

30/4-2 |

923 |

510 |

835 |

40/50 |

730 |

335 |

428 |

100 |

20 |

130 |

|

30/6-2 |

908 |

510 |

835 |

40/50 |

730 |

335 |

428 |

150 |

20 |

142 |

|

60/4-2 |

933 |

545 |

1,081 |

50 |

734 |

330 |

484 |

150 |

20 |

390 |

|

60/6-2 |

968 |

555 |

1,081 |

50 |

734 |

330 |

484 |

150 |

20 |

390 |

|

85/8-3 |

1,114 |

769 |

1,290 |

80 |

1,028 |

521 |

600 |

200 |

40 |

415 |

MAXFLO® model:

|

Models |

MAXFLO® dimensions in mm |

Weight in kg |

||||||||

|---|---|---|---|---|---|---|---|---|---|---|

|

|

A |

B |

C |

E |

F |

G |

H |

J |

K |

|

|

114/4-4 |

1,269 |

400 |

337 |

162 |

1,190 |

543 |

200 |

50 |

102 |

335 |

|

114/8-8 |

1,279 |

400 |

337 |

162 |

1,190 |

543 |

200 |

50 |

102 |

455 |

|

228/8-5 |

1,503 |

400 |

337 |

241 |

1,252 |

535 |

200 |

50 |

127 |

525 |

|

342/8-6 |

1,725 |

400 |

327 |

252 |

1,285 |

533 |

200 |

63 |

152 |

555 |

|

342/12-6 |

1,807 |

400 |

327 |

235 |

1,131 |

521 |

300 |

63 |

152 |

753 |

|

570/12-8 |

2,026 |

400 |

400 |

219 |

1,127 |

435 |

300 |

76 |

203 |

1,157 |

|

857/12-10 |

2,276 |

480 |

502 |

305 |

1,153 |

375 |

300 |

76 |

254 |

1,501 |

|

1428/12-12 |

2,956 |

480 |

502 |

337 |

1,607 |

781 |

300 |

76 |

305 |

2,019 |

|

2125/16-12 |

3,680 |

480 |

495 |

305 |

1,607 |

781 |

400 |

101 |

254 |

2,450 |

|

2825/16-12 |

4,230 |

480 |

502 |

337 |

1,848 |

898 |

400 |

127 |

305 |

3,130 |

|

3500/16-12 |

4,759 |

480 |

502 |

337 |

2,247 |

1,092 |

400 |

153 |

305 |

3,850 |

Particle size: from very fine (ash) to big (peanuts)

Overpressure average level: 4 bars

Manufacturing: cast iron, 304L and 316L stainless steel

Compressed air consumption: 2 to 114 Nm³/min.

Maximum conveying distance: 700 m.

ATEX Certification: zone II 1,2,3 GD (EMI less to 3 mJ)

Maximum temperature: 280°C

Maximum operating temperature: > 300°C

Inlet Ø: 50 to 600 mm.

Integrated equipment :

- Vent line

- No baffle, nozzles or fluidization jets

- Volume of the sas

- Low and controlled velocity

- Conveying compressed air supply

- Control box

- Valve for break in the product stream

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Packing of white, organic and brown sugar

Processed powders: refined white sugar and brown sugar - Packing of white, organic and brown sugar - Leader in Africa and the Mediterranean Basin in the sugar industry and vegetable oil industry.Food and Animal Feed

Incineration plant

Processed materials: ashes - Incineration plant - Leading company in the supply of waste management and recovery solutions, expert in the whole waste cycle.Water and smoke

Drinking water filtration

Powder processed: activated carbon and lime (with a respective bulk density of 0.5 ton/m³ and 0.6 ton/m³) - Drinking water filtration - The customer requires a pneumatic conveying system, at a rate of...Water and smoke

Filling of truck with cement

Processed product: cement - Filling of truck with cement - Two EasyFlow® EF100 big bag unloading stations for high-speed semi-automatic unpacking.Minerals and building