Description

The efficient and flexible solution for powder and bulk packaging processes subject to strict hygienic constraints. The weighing system is incorporated into the filling head setup which reduces product retention and entrapment areas on the ground.

FlowMatic® 05-HC - Hydraulic cylinder

The FlowMatic® 05-HC series incorporates a hydraulic cylinder for the raising and lowering of the FIBC. This mechanism provides an efficient and flexible solution for powder packaging operations subject to strict hygienic constraints. By eliminating product retention areas on the ground, the suspended weighing "platform" instead is directly installed on the filling head.

-

Automation4

-

Rate3

-

Overall dimensions4

FlowMatic® 05-HC procedure:

1. Place the bulk bag on the packing station

2. Seal the bulk bag inlet by inflatable seal

3. Raising of the bulk bag via the hydraulic cylinder

4. FIBC is inflated with pre-forming fan and then switched to venting system

5. Bulk bag filling commences at a high flow rate

6. Weight management: gross weighing control by slowing down filling rate for final dosing

7. Filling sequence is complete: lowering of the hydraulic cylinder, deflating of the seal and automatic release

8. Removal of the bulk bag by pallet truck or forklift

Equipment advantages

- Automatic unhooking of the loops for ergonomics and safe handling

- Suspended structure to facilitate floor cleaning

- Filling head in double casing to prevent back pressure of the bulk bag during packaging

- Inflatable seal for dust containment and a stable connection

- Sanitary bulk bag filling

Media

View our equipment in videos

Remplissage big bags FlowMatic 05

Conditioning with suspended bulk bag and gross weighing

Efficient and flexible solution for powder conditioning process subjected to high hygienic constraints: reduction of retention areas on the ground by the setting up of a weighing platform directly fitted on the filling head.

Bulk bag filling range

FlowMatic®05 HC - Bulk bag filling unit - Hydraulic cylinder

FlowMatic® 05 HC Big bag filling

View our equipment in photos

Big bag filling food powder

Hygiene and ergonomics for the operator for an application in the food industry.

Big bag filling - Hydraulic cylinder

The big bag is placed on the pallet using a hydraulic cylinder.

Big bag filling line

Conditioning of minerals in big bags.

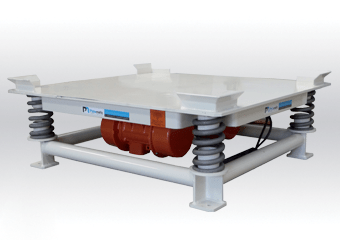

Suspended weighing - Big bag filling system

The ground retention areas are reduced by installing the weighing system directly on the filling head of the big bags filling station.

Bulk materials handling

Hygienic and ergonomic big bag conditioning line.

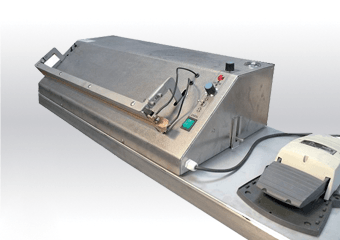

Ergonomic handle

The handles of the big bag are ergonomically designed to facilitate operator intervention.

Suspended weighing

The load cells that carry out the dosing of powder and bulk materials are suspended on the structure of the big bag filling station.

FlowMatic® 05 - Hydraulic cylinder

The hydraulic cylinder is positioned on the main structure of the big bag filling station.

Load cells

Integrated weighing system on the big bag filling station.

Bulk bag conditioner - FlowMatic® 05

The suspended dosing system ensures the dosing and regulation of powders for packaging operations and allows the printing of weighing labels with history.

Remplissage big bag avec pesage suspendu

The load cells are directly positioned on the forks of the filling station.

Conditionnement des big bags en pesée brute

La dépose du big bag sur sa palette après remplissage est réalisée via un vérin hydraulique.

Features

Technical specification

| Rate | 10 to 20 bulk bags/h. |

|---|---|

| Capacity | 2 tons/bulk bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 1.6 kW |

| Compressed air consumption | 2.9 Nm³/h. |

| Dust removal rate | 300 m³/h. |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 0.2 kW

Operating pressure: 6 bar

Input 4-20 mA: 1

Digital input: 3

Digital output: 5

Accuracy of the weighing chain: ± 500 grams

Maximum dimensions of big bag Length x Width x Height: 1,550 x 1,550 x 2,400 mm

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Lime and mineral packing

Processed powders: lime + additives - Lime and minerals packing - The installation involves a FlowMatic® 05 big bag filling station with suspended weighing.Minerals and building

Receive our quotation in 3 clicks!