Description

FlowMatic® 06 Bulk bag filler - 100% Automation for Net Weighing at High Rate Capacities

The complete system solution for automatic filling of bulk bags in net weighing operations. This model is ideal for continuous filling operations at high rates (30-60 bulk bags/hour) and minimizes the need for direct intervention by production operators.

The Flowmatic® 06 automated super sack filler is equipped with all necessary options for fast packaging of bulk bags, such as: pre-dosing weigh hopper, inflatable containment seal, automatic handle release system, pneumatic cylinder for height adjustment, pre-forming fan, commercial weighing, vibrating densification table, pallet feeder and a motorized roller conveyor.

-

Automation5

-

Rate5

-

Overall dimensions4

1 - Pallet unstacker

2 - Motorized conveyors

3 - Automatic release

4 - Inflatable seal

5 - Head

6 - Tension cylinder

7 - Vibrating table

8 - Load cells

9 - Pre-dosing hopper

10 - Platform

The Flowmatic® 06 bulk bag loading system represents the complete solution for automatic net weighing of big bags, FIBCs, super sacks, jumbo bags and bulk bags (dosing, packaging, conveying, etc.). This model is designed for continuous use at high throughput rates while integrating automatic operation features to minimize the need for human intervention.

FlowMatic® 06 operation procedure:

- The pallet feeder automatically places an empty pallet on the motorized roller conveyor to supply the bulk bag filling station.

- The operator loads the empty bulk bag thanks to the automatic rear hook feed system

- The bulk bag inlet spout is fitted to the filling head via the inflatable seal for dust containment.

- To optimize the filling volume of the bulk bag, the pneumatic cylinder adjusts the height and tension on the FIBC.

- A pre-forming fan inflates the bulk bag to prevent wrinkles for optimal filling capacity.

- A bypass valve switches the inflation fan to an exhaust system for volume balancing and possible connection to a central dust collection system.

- The material fills the bulk bag and, in hidden time, the next batch of material is prepared in the weighed hopper above.

- Positioned under the bulk bag is the vibrating table which densifies the material to promote stability of the bulk bag.

- The filling cycle is complete, deflating the bulk bag seal and automatically releasing the hooks that hold the bulk bag handles.

- The bulk bag is automatically transferred to a buffer storage area via the motorized roller conveyor.

Equipment advantages

- Handling conveyor for automatic high rate filling

- Pallet unstackers with a capacity of 15 multi-format pallets

- Net weighing dosing hopper for containment and automation

- Simple unloading operation of filled bulk bags by forklift

Media

View our equipment in videos

Automatic big bag filler

Customer application: Automatic big bag filling and sugar dosing.

Semi-automatic big bag packaging line for fish meal

Semi-automatic big bagging of fish meal.

Big bag filling - Flowmatic 06

Big bag filling - Flowmatic 06 100% automated bulk bag loader with net weighing for high rate loading

Bulk bag filling range

View our equipment in photos

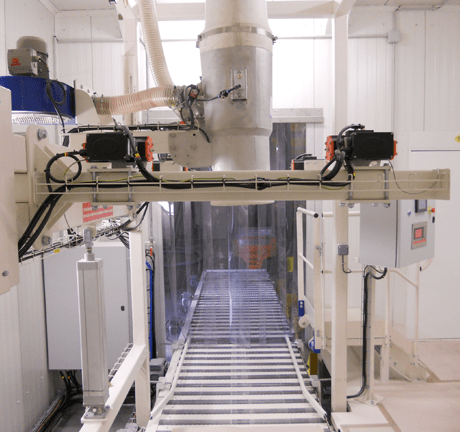

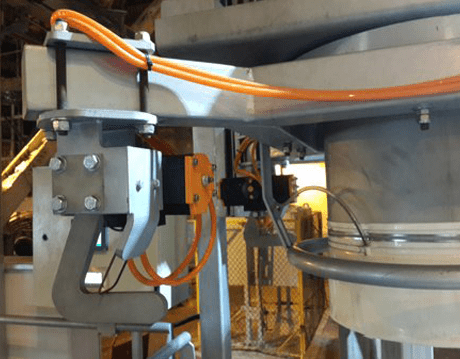

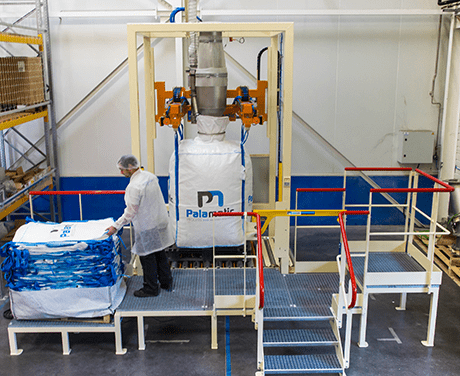

Palamatic Process Bulk bag filling

Motorized roller conveyor on big bag filling station.

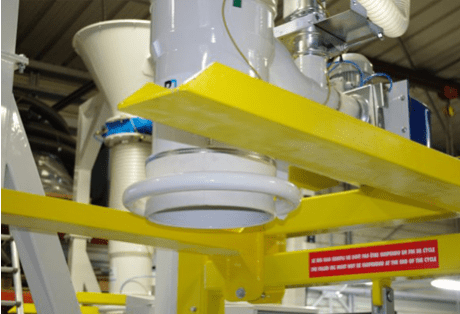

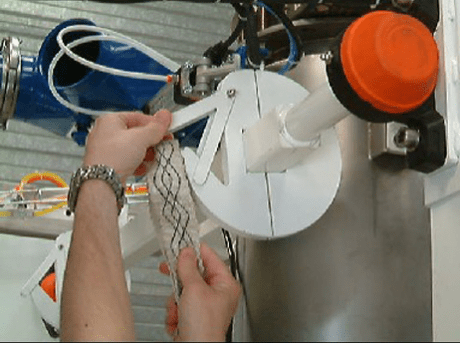

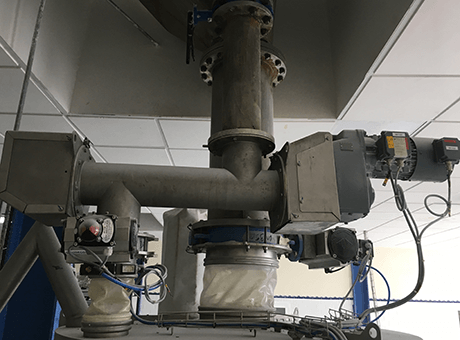

Inflatable seal

Shown here, the inflatable seal provides a dust tight connection to your bulk bag inlet spout.

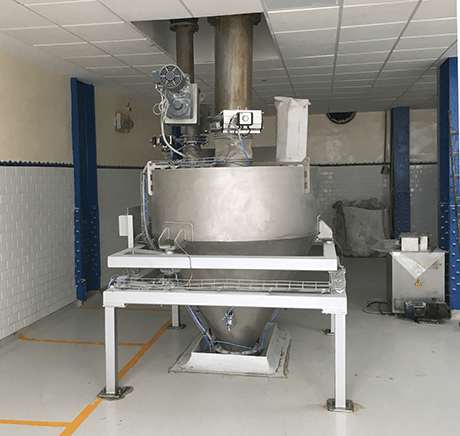

Bulk bag filling - Bulk materials handling system

Automatic super sack loader with net weighing for high rate filling operations.

The complete solution for automatic super sack filling by net weighing operation. The bulk bag filler is perfect for continuous use with high flow rates (30-60 bulk bags/hr) and minimize the need for intervention by operators.

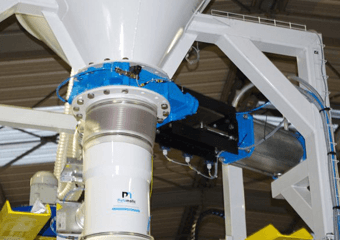

Big bag packing production line

The dosing hopper for feeding the big bag filling station is equipped with load cells.

Automatic release hooks

The bulk bag straps are automatically released once the filling cycle is complete.

Big bag filling head

The belt conveyor provides motorized evacuation of the big bag once it is filled.

FIBC loading

Loading of big bags on industrial production lines processing bulk materials.

Bulk bag evacuation

Once filled, the bulk bag is transferred to a buffer area by the motorized roller conveyor. From there a forklift operator can take the bulk bag away.

FIBC handling

Net weighing and commercial transaction are the benefits of the FlowMatic® 06 big bag conditioner.

Bulk bag loading

High efficiency and ergonomic design are some of the major benefits of the FlowMatic® 06 bulk bag packaging system.

Bulk bag raw material packaging

Seen in this image, the bulk bag is automatically released by the handling hooks once the material filling process is complete.

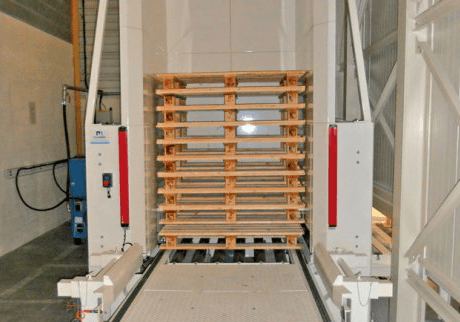

Pallet unstacker

The pallet unstacker has a capacity of 15 multi-format pallets.

Bulk bag filling system powder handling equipment inflatable containment seal

The inflatable containment seal provides the filling of the bulk bag in a secure manner without risk of dust and debris getting into the production atmosphere.

Handling conveyor on bulk bag filling line

Conditioning of minerals in big bags.

Bulk materials handling

Packing station for big bags of seeds.

Big bag filling line conveyor

The big bags of sugar, once filled, are moved using a roller conveyor.

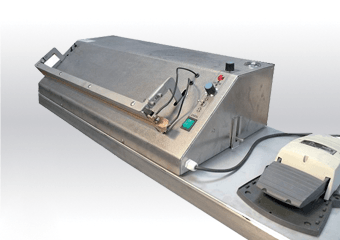

Welding machine for bulk bag sealing

The thermo-welding system allows the operator to tightly seal off the bulk bag after the material filling sequence.

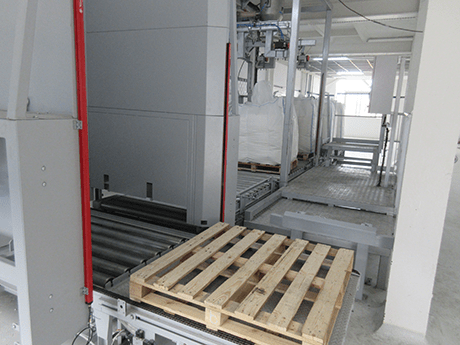

Automatic pallet feeder

The stacked pallets are stored in the magazine capacity of the automatic feeder. One by one they are placed onto the motorized roller conveyor and transferred to the bulk bag packing station.

Hopper on bulk bag filling processing line

Dosing hopper upstream of the big bag filling machine for a biscuit processing line.

Bulk bag packing

This system installation transfers the material from an existing silo via a screw conveyor to the bulk bag filling station.

Filling super sacks with bulk materials

The FlowMatic Series by Palamatic Process: Bulk bag storage solutions for bulk materials.

Big bag filling with sugar

The installation of a roller conveyor provides high filling rates.

Speed control for bulk bag filling

Bulk bag filling with animal flour from a high and low rate adjustable screw conveyor.

Rotating filling head for bulk bags

The rotating head provides ergonomic access for the operator to place the bulk bag handles on the automatic release hooks.

The FlowMatic06 bulk bag filling system

Industrial production line for the automatic filling of super sacks shown here with an operator access platform.

Bulk bag material filling application with feeding hopper

Palamatic Process has developped a high speed super sack packaging system with hygienic features. The objective is to condition the bulk material being fed from a blower truck into the buffer hopper that fills the bulk bags.

Bulk bag powder filling line

Filled bulk bags of sugar are transferred by means of a roller conveyor.

Features

Technical specification

| Rate | 30 to 60 bulk bags/h. |

|---|---|

| Capacity | 2 tons/bulk bag |

| Manufacturing materials | Painted steel, 304L stainless steel |

| Installed power | 11.7 HP |

| Compressed air consumption | 353 CFM |

| Dust removal rate | 600 m³/h. |

Finishing touches: RAL 9006, micro-blasted, electropolishing

Average power consumption: 2 HP

Operating pressure: 6 bar

Input 4 - 20 mA: 1

Digital input: 15

Digital output: 13

Accuracy of the weighing chain: ± 500 grams

Maximum dimensions of big bags: 47,25" (L) x 47.25" (W) x 94.5" (H)

Equipment integrated into the FlowMatic® 06 model:

- Pre-weighed dosing hopper

- Motorized roller conveyor

- Pre-inflation fan

- Automatic bulk bag unhooking

- Tension cylinder

- Vibrating table for densification

- Pallet unstacker

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Packing of white sugar and crystal sugar in bulk bags

Processed powders: granulated white sugar, surfine caster sugar, crystal sugar - Packing in bulk bags of white sugar and crystal sugar - This bulk bag installation is designed to achieve a minimum...Food and Animal Feed

Powdered sugar packaging

Processes powder: powdered sugar - Powdered sugar bagging - Our client is a company specializing in sugar manufacturing with a need to increase production capacity to meet the rising demand by global...Food and Animal Feed

Loading bulk bags of soda ash

Treated powder : Natural soda ash - Automatic bulk bag filling line with buffer hoppers. Remote control system ensuring traceability and safety of the process.Chemical

Your quotation in 3 clicks!