Processed product: tomato powder

Industrial process for tomato-based products

Manufacturer of tomato sauce and tomato powder from fresh tomatoes.

The application requested by the customer is the placing in bulk bags and boxes at the outlet of an atomization tower.

The customer needs equipment design to meet the hygienic standards for packaging food-based powder in bulk bags and boxes.

Customer data:

Cardboard boxes: 40 to 50 lbs.

Bulk bags: 1,000 and 2,000 lbs.

Feed rate: 2 tons/hr

Density: between 26 and 31 lbs/ft³

The entire line is protected by a safety magnetic system. A powder sampler ensures product quality control for the production teams. A buffer hopper equipped with a two-way transfer screw feeds the bulk bag, or the box line.

The operation is carried out under a controlled atmosphere and the packaging is sealed by double welding bars.

Bag/box line

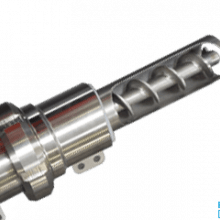

The operator positions the bag on the weighed packaging head. The hygienically designed twin-screw feeder ensures the dosing of the product with a flexible sleeve connection to avoid any weighing interference.

The welder incorporates a vacuum system and nitrogen injection into the packaged product to preserve freshness. The lifting and transfer of the filled boxes is done by a suction seal manipulator.

Bulk bag line

The bulk bag line, installed in parallel with the box line, provides the hygienic packaging of the super sack and accurate dosing of the packaged material. The filled big bags are positioned on a wooden pallet. However, the use of the FlowMatic® 04 H model avoids the introduction of pallets into the packaging area.

The principle of operation is docking the big bag on its pallet via a double-level conveyor. The big bag is conveyed via a motorized belt to the packaging area.

This solution meets the required hygienic constraints with a reasonable investment compared to an aerial handling solution for bulk bags.

The dosing devices are of hygienic design with easy dismantling, as can be seen in our Easy Clean range of industrial process equipment.