Description

Dilute phase pressure pneumatic conveying

This pneumatic conveying is designed to carry bulk products, powders and granules at high flow rates over long distances.

Cys range

Dilute phase pneumatic conveying with booster for powders, bulk materials

This pneumatic conveyor for powder handling in dilute phase, generally thrust, allows to carry powders and bulk materials at high throughput rate along important distances (not fragile materials). This pneumatic conveyor in dilute phase lies in the use of rotary airlocks (rotary valves) allowing to introduce measured doses of material in the piping.

Regular application of pressure pneumatic conveyor in dilute phase : silo emptying and silo filling.

Integrated equipment :

-

Rate4

-

Fragile material4

-

Abrasive material2

Equipment advantages

- When using dilute phase pressure pneumatic conveying, the material dilution rate in the air is very important, and therfore requires a high throughput rate of air to convey the material.

- The greatest advantage of dilute phase pressure pneumatic conveying is the ability to supply several reception points as from a supply point.

Media

View our equipment in videos

Pneumatic conveying - Dilute phase pressure

View our equipment in photos

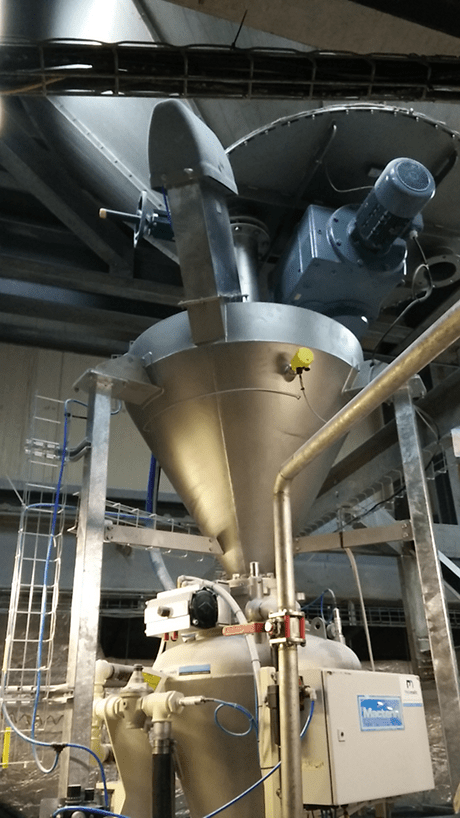

Gamme CYS

Gamme de transfert pneumatique poussé phase diluée.

Cyclofilter pneumatic transfer - Palamatic Process

The cyclofilter or pneumatic pressure transfer from Palamatic Process consists of conveying materials by creating a positive pressure inside a sealed pipe.

Pneumatic conveying cocoa

Pneumatic conveying for the handling of industrial bulk materials.

chemistry application cyclofilter

Feeding of the pneumatic conveying station from a bag emptying station with a weighed hopper to prepare the doses in bags to be incorporated.

Fine chemistry application cyclofilter

This set is intended for transporting gelatin to a weighing hopper. The gelatin is extracted from the big bags. The conveying is carried out by a vacuum pump and a cyclo-filter equipped with a rotary valve to maintain the vacuum while feeding the hopper with powders.

Reception cyclofilter pneumatic conveying

Pneumatic conveying system for feeding a weighing hopper.

Pneumatic conveying powder treatment cyclofilter

The process is designed to load two melters from two big bag discharging stations.

Possibility of simultaneous conveying to the two melters with pneumatic vacuum conveying with detached filtration.

Cyclofilter Palamatic Process

Pneumatic conveying by overpressure at a flow rate of 40 t./h.

Pressure pneumatic conveying

Pneumatic conveyor for supplying of several reception points.

Bulk materials handling pneumatic conveying

The high pressure dilute phase conveying technology can be used to integrate 2 weighing solutions: weight loss and weight gain.

High flow cyclofilter on Palamatic installation

High flow cyclofilter on Palamatic installation for the transfer of your bulk and powdered products.

Pneumatic conveying dilute phase pressure

Continuous feeding of a Palamatic Process industrial mill for the production of icing sugar.

Pneumatic conveying dilute phase

Discharge of polypropylene bags for truck filling.

Pneumatic conveying

- Long-distance pneumatic conveying

- High speed

- Ease of implementation

- Multi-point power supply

Pneumatic conveyor

Pneumatic conveying by overpressure.

Dilute phase pneumatic conveying

It is used to convey bulk, raw ingredients, powder and granular materials at high throughput over long distances.

Pneumatic conveying dilute phase pressure

3 technologies:

- Cyclofilter

- Expansion vessel

- Silos

Pneumatic conveying under hopper

Feeding of the mixing line from raw material silos.

Pneumatic conveying of starch and granules

For collection under big bag discharge station.

Pneumatic conveying process line

Pneumatic conveying fed by an automatic bag unpacking line for truck filling.

Pneumatic conveying of alumina

The pneumatic conveying system feeds the storage silo which is fitted with a dust collection system.

Pressure pneumatic conveying

The dilute phase pressure pneumatic conveying circuit is supplied by a blower.

Cyclofilter in fine chemistry application

The conveying cyclone is directly installed on the hopper and a flexible pipe system prevents interference with the load cells.

Cyclofilter

Multi-arrival pneumatic conveying from a combined big bag and sack emptying station Duopal®. The abrasiveness of the bulk material has been taken into account.

Cyclofilter for reactor fedding

Industrial production line for feeding a reactor including an industrial dust collection system on a storage and conveying line for powders to a reactor (processed powders: arenox, rosinox, irganox and pentaerythrite).

Dilute phase cyclofilter with pneumatic transport Palamatic

Dilute phase push cyclofilter with industrial booster sending air under pressure.

Features

Technical specification

A booster sends air under pressure (with control) by a valve in the conveying piping at a high speed (24 to 30 m./s).

This air is mixed with the bulk material and conveyed up to the end of the line. In most cases, air-product separation is ensured by a filtration system followed by a reception hopper and a distribution rotary valve (in most cases).

| Models | Filter surface in m³ | Housing Ø | Connection Ø | Operating volume | Cyclofilter discharge Ø |

|---|---|---|---|---|---|

| CYS 01 | 3 | 800 | 60.3 | 300 | DN 200 |

| CYS 02 | 3 | 800 | 76.1 | 300 | DN 250 |

| CYS 03 | 5 | 1,000 | 88.9 | 445 | DN 300 |

| CYS 04 | 6 | 1,200 | 104 | 515 | DN 300 |

| CYS 05 | 12 | 1,200 | 139.7 | 905 | DN 350 |

| CYS 06 | 15 | 1,400 | 168.3 | 1,320 | DN 350 |

| CYS 07 | 30 | 1,700 | 219.1 | 2,275 | DN 350 |

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Animal feed

Processed powders: food additives - Animal feed - Specialist in additives for animal feed.Food and Animal Feed

Bulk truck loading

Processed powder: polypropylene - Bulk truck loading - This powder handling line is designed to feed granules into trucks at a high rate of 25 t/h. The production requirement is to create neither...Chemical

Blower for feeding containers

Processed materials: crushed egg shells - Blower for feeding containers - The purpose of the equipment is to collect crushed egg shells from a centrifuge / crusher placed downstream of automatic...Food and Animal Feed

Discharge, Feed and Grinding Line

Processed bulk material: Lysine - Grinding Line - Facility for one of the world's leading animal nutrition companies.Food and Animal Feed

Flour unloading

Processed powder: wheat flour - Tank unloading - Flour unloading from tanks to storage silosFood and Animal Feed

Loading silos with sugar

Processed materials: crystal sugar - Loading silos with sugar - A container tipper is used to feed the high pressure pneumatic conveying network to feed 2 silos of 50 tons.Food and Animal Feed

Refined sugar conveying

Processed material: refined sugar - Refined sugar conveying - On-site installation of repackaging equipment for the transfer of sugar stored in shipping containers with an inner liner to a bulk bag...Food and Animal Feed

Glue production unit

Processed powders: polyester powders - The powder is delivered in big bags or sacks for storage in a weighed buffer hopper.Chemical

Unloading big bags containing grains and cereals

Process products: wheat bran, wheat flour, disinsected wheat bran - Unloading big bags containing grains and cereals - This big bag emptying station aims to feed insects (larvae and adults) with dry...Food and Animal Feed

Insect breeding unit

Processed products: bran, meal, droppings, live insects, dead insects - Insect breeding unit - This workshop is the heart of the insect breeding process.Food and Animal Feed

Unloading and filling of manganese dioxide big bags

Processed powder: lithium nickel potassium oxide - Unloading, filling of big bags and transfer of material - The objective of this installation is to protect the operators with equipment designed to...Energy

Process for feeding mixers

Processed powders: potato flakes, semolina, salt, breadcrumbs - New workshop for the production of fillings - Unloading, transfer, storage, dosing.Food and Animal Feed

Process for the production of chocolate

Process materials: granulated Sugar, whey, skim milk powder, and various other minor additives - Process for the production of chocolate - Objectives: unloading, transfer, storage and dosing of...Food and Animal Feed

Railcar unloading

Processed powders: tapioca starch, potato starch, corn starch - Unloading of railcars - Line for powder repackagingFood and Animal Feed

Flour handling on production line

Processed powder: flour - Handling of flour on a manufacturing line - Production process in industrial bakery - Flour feedFood and Animal Feed