Description

Big bag deconditioning station and bag stripping box

The loading can be carried out by electric hoist; by forklift or low structure via the use of a forklift, an overhead crane...

This standard equipment allows the emptying of your powders and bulk products in a confined way for your big bags and bags.

3 types of loading are available:

The emptying station allows the ergonomic deconditioning of big bags and bags with the use of an electric hoist, a forklift truck or an overhead crane and available in a low version.

Electric hoist loading

Made of painted steel, 304 stainless steel and 316 stainless steel

PALAMATIC PROCESS has developed standard unloading stations to meet the needs of industries that load their processes with big bags and all types of bags (25/50 kg) on the same unloading point.

2 standard sizes available (reduced delivery time) big bags passage width: 1,250 mm and 1,500 mm.

This station allows the deconditioning of big bags and bags ergonomically and the use of an electric hoist. Dust emissions are reduced as much as possible by putting an effective containment device in place (dust skirt, containment tube, capture nozzle). The flow of the product is optimized by the introduction of a vibrating plate (vibrating motor) or an optional pneumatic massage system.

The introduction of big bags and bags by electric hoist allows all operators to ergonomically and autonomously load the powders in the process.

In addition, this type of station offers great flexibility as to the size of the big bags and bags used. Standard big bag emptying stations can empty big bags and bags over 2,200 mm high.

The access to the big bag emptying sleeve is ergonomic due to the dimensional respect of the viewing height. The airtight door combined with the anti-overflow tube ensures total containment during the opening and emptying of big bags and bags

Forklift truck loading

Deconditioning station designed for the use of a forklift truck and a handling cross to accurately position the big bags on the dispensing tray.

PALAMATIC PROCESS has developed standard unloading stations to meet the needs of industries that load their processes with big bags and all types of bags (25/50 kg) on the same unloading point.

2 standard sizes available (reduced delivery time) passage width of big bags: 1,250 mm & 1,500 mm.

This station allows the deconditioning of big bags and bags ergonomically. The big bag is placed on the deconditioning station by a forklift truck and a specific big bag handling cross. Dust emissions are reduced as much as possible by putting an effective containment device in place (dust skirt, containment tube, capture nozzle). The flow of the product is optimized by the introduction of a vibrating plate (vibrating motor) or an optional pneumatic massage system.

The positioning of big bags and bags by the forklift operator is secured by the specific handling cross and the positioning on the centring structure. When depositing the big bag and bag in the unloading station, the handling cross is indexed in centering devices offering safety and ease of positioning.

In order to accommodate the different dimensions of big bags and bags, the station is height-adjustable via a telescopic sleeve system with piggyback locking.

This robust and efficient technology can empty big bags and bags over 2,200 mm in height.

Low structure loading

The installation of big bags on the deconditioning station via a forklift truck, an overhead crane and a handling cross.

PALAMATIC PROCESS has developed standard unloading stations to meet the needs of industries that load their processes with big bags and all types of bags (25/50 kg) on the same unloading point.

2 standard sizes available (reduced delivery time) big bags passage width: 1,250 mm and 1,500 mm

This station allows the deconditioning of big bags and bags ergonomically. The installation of the big bag on the deconditioning station is provided by you through the use of a forklift, a crane... A big bag handling cross is provided by PALAMATIC PROCESS to ensure the safe handling of big bags. Dust emissions are reduced as much as possible by putting an effective containment device in place (dust skirt, containment tube, capture nozzle). The flow of the product is optimized by the introduction of a vibrating plate (vibrating motor) or an optional pneumatic massage system.

The installation of big bags and bags is ensured by your handling equipment (trolley, overhead crane, jib crane...) coupled with the use of the big bag handling cross.

The handling and unloading operations are secured by the deposit tray avoiding any risk of falling. The operator works in conditions of optimum safety and ergonomics.

Our equipment is delivered with a CE declaration of conformity and the passage of control bodies such as: APAVE, NORISKO... can be handled by Palamatic Process on request.

Big bag and bags unloading - Duopal® - Custom

Opening bags and big bags at the same unloading point

Customized solutions, closer to the expectations of industrialists, based on precise specifications.

Simultaneous unloading of 25/50 kg bags and big bags

The innovative PALAMATIC PROCESS solution reduces the space requirement to a minimum and facilitates the loading of raw materials. The PALAMATIC PROCESS design office offers customized unloading solutions according to all your operating and site constraints. Together we define the customized solution according to your precise specifications.

Built-in features:

- Automatic cutting of big bags & bags

- Extensive containment

- Extraction of very difficult products

- Very low installation height

- Ergonomics of the workstation

- Compacting of empty big bags and bags integrated in the station

- ATEX

-

Rate2

-

Automation1

Equipment advantages

- Connection tube: totally airtight connection between the big bag and the unloading station.

- Containment tube: ensures a containment of the produt flow during the opening phase of the drain sleeve and offers the operator.

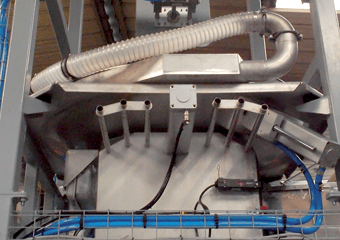

- Massage deposit tray: the flow of the product is optimized by the installation of a pneumatic massage system.

- Cardboard deconditioning: the opening of the emptying station allows the deconditioning of different types of containers, bags, cartons...

Media

View our equipment in videos

Discharging cement big bags

Discharging big bags of cement

Duopal - Big bag & sack discharging

View our equipment in photos

Duopal® big bag and sack unloading station with tray

Big bag and sack unloading station equipped with a shelf for ergonomic access for the operator.

Duopal - Unlacing cabinet

Discharging of sacks and bulk bags on the same frame.

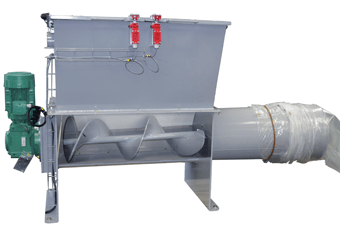

Forklift truck loading

Dust-tight big bag and sack discharger with stripping box.

Electric hoist loading

Big bag and sack discharger with electric hoist loading. An optional massage system is integrated.

low profile loading

This frame is used to discharge big bags and sacks in an ergonomic way using an electric hoist, a forklift truck....

Duopal® big bag unloading station - Unloading box

Complete Duopal® big bag and sack unloading station with integrated unloading box.

Big bag & sack discharging - Unlacing cabinet

Bulk bag and sack discharger self-supporting structure adjustable in height and width.

Untying box

Discharging of sacks and bulk bags using same frame.

Automatic sack opening

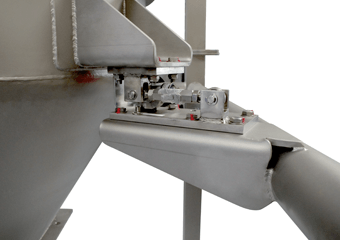

Bulk bag and sack dischargers are available mounted on load cells.

Iris valve

System that regulates or stops the bulk materials.

Big bag discharging system - untying box

Discharging of pigment in a paint manufacturing process.

Big bag discharging system - Unlacing cabinet

Vacuuming of the big bag to avoid any dust emission.

Bulk materials discharging

Standard big bag discharge station using hoist loading.

Sack discharging system - untying box

Stripping box with leak-proof door.

Double unloading station

Double big bag and sack discharger, loading by lifting truck.

Duopal - Unlacing cabinet

Duopal® : Bulk bag & sack discharger with stripping box, electric hoist loading

Bulk bag & sac discharging

The Duopal® combined sack and big bag discharger has made it possible to save substantial space while allowing the loading of a wide variety of raw materials.

Bulk bag & sac discharging system

The flow of the material is optimized by the installation of a pneumatic massage system with activators.

Bulk bag & sac discharging - Unlacing cabinet - DP0

Discharging of TiO2 for the manufacture of cosmetic products.

Bulk bag & sac discharging - Unlacing cabinet

Discharging of TiO2 for the manufacture of cosmetic products.

Jumbo bag & sac discharging

Chemical powder discharging for the manufacture of adhesives.

Jumbo bag & sac discharging - adhesive manufacturing

Bulk materials discharging for the manufacture of adhesives in the chemical industry.

Jumbo bag & sac discharging - Electric hoist loading

Bulk handling for the manufacture of adhesives in the chemical industry.

Adhesives manufacturing line

Raw ingredients handling for the manufacture of adhesives in the chemical industry.

Big bag & sac discharging - Electric hoist loading

Paint manufacturing using a big bag and sack discharger.

Duopal unlacing cabinet

Bulk bag and sack discharger for industrial production lines.

FIBC and sack unloader

Bulk bag and sack discharger with an integrated platform.

FIBC and sack unloader - Unlacing cabinet

Discharging of animal flour from big bags and sacks.

FIBC and sack unloader - Untying box

Discharging of corn starch for the production of ready-to-eat meals.

Bulk bag and sack unloading - Untying box

Bulk bag and sack discharger for industrial production lines involving raw ingredients and bulk materials handling.

Bulk bag and sack unloading

Sack and big bag discharging for the handling of all types of industrial powders and bulk materials.

Duopal : Big bag and sack unloading

Possibility to unpack cardboard boxes.

Duopal® big bags and sacks emptying station - Palamatic

The Duopal® big bag and sack emptying station Palamatic has an access door equipped with clamps for closing.

Duopal : Jumbo bag and sack unloading

Containment tube to ensure containment during the opening phase.

Duopal® bulk bags and sacks unloading station by Palamatic Process

Combined station for the unloading of bulk bags and sacks (50-100 lbs) on the same frame.

Sacks and bulk bags discharging

Unloading station for bulk bags and sacks on industrial lines in the petrochemical sector.

Sack opening station on bulk bag discharging station

De-packaging of powders and bulk stored in bulk bags and sacks.

Powder emptying and packaging

The access area to the industrial storage container is protected by an enclosure.

Big bag and sack emptying station

The storage container is connected to the station by means of a flexible connection sleeve.

Filling container under big bag emptying station

The big bag and sack emptying station Duopal® is positioned above the storage container.

Features

Technical specification

| Rate | 10 to 30 big bags/h - 180 sacks/h |

|---|---|

| Capacity | 2 tons / big bag |

| Manufacturing materials | Painted steel, 316L stainless steel |

| Installed power | 0.1kW/2.97 kW (with hoist) |

Big bag and bag unloading station with electric hoist loading: item code: DP01 125 & DP01 150.

Equipment integrated on the standard versions (excluding options):

- Self-supporting structure with hoist iron and tracking rail: allows the safe installation of big bags and bags via the electric hoist by all operators

- 5-point handling cross: allows to fix the inner pocket of big bags

- Deposit tray: ensures that the big bag and bag are held during unloading and secures handling operations

- Sealing skirt: optimizes containment by capping the bottom of the big bag and the bag

- Vibrating motor: ensures the vibration of the deposit tray to facilitate the extraction of the powder

- Stripping box with airtight door: offers secure and ergonomic access to the big bag and bag drain sleeve

- Anti-overflow tube: allows the product flow to be channelled into the stripping box and facilitates operator handling

- Protective screen: ensures clean powder supply without foreign body (mesh size 50 x 50)

The stations can be built in painted steel, hot-dip galvanized steel, 304L stainless steel or 316L stainless steel. The parts in contact with the products and the structure can be made of different materials.

Options

Case studies

CASE STUDIES WITH THIS EQUIPMENT

Infant milk powder line

Processed bulk solids: milk powder - Infant milk powder line - This subsidiary company from one of the first milk group in the world, devellops a wide range of functionals and nutritionals milk...Food and Animal Feed

Wheat bran and lime premix line

Processed powders: wheat bran and lime with a bulk density of 0.4 to 1 kg/m³ - Wheat bran and lime premix line - Estonian engineering company specialized in the design of industrial operations for the...Food and Animal Feed

Animal feed

Processed powders: food additives - Animal feed - Specialist in additives for animal feed.Food and Animal Feed

Powdered egg production

Processed powders: salt and sugar - Powdered egg production - This customer is a specialist in egg processing for industrial customers. This manufacturing process requires an aqueous solution that...Food and Animal Feed

Premix manufacturing

Processed powders: silica, wheat, carbonate - Premix manufacturing - The installation consists of a new mixing line for the production of natural additives for animal nutrition.Food and Animal Feed

Frozen fruit process

Processed bulk solids: blackcurrent, cherries, bananas, raspberries, peaches - Frozen fruit process - IQF (Individually Quick Frozen) big bag and cardboard box discharger.Food and Animal Feed

Unloading big bags containing grains and cereals

Process products: wheat bran, wheat flour, disinsected wheat bran - Unloading big bags containing grains and cereals - This big bag emptying station aims to feed insects (larvae and adults) with dry...Food and Animal Feed

Production of dried fruits and seeds

Processed powder: dried fruits and seeds - Mixing and packaging - Our customer wanted to implement a new production line in its plant to support its growth.Food and Animal Feed